Sinofork special-shaped shuttle successfully landed at Shengxin Furniture!

Shengxin Furniture · Special-shaped Shuttle Project

Project pain points

A case of Sinofork special-shaped shuttle vehicle successfully applied in the furniture industry. The project is located in Shengxin Furniture, Anji County, Zhejiang Province. Because the size and structure of traditional conventional shuttles are based on standard pallets, when the size of the goods that need to be transported and stored is large, the number of goods transported by conventional shuttles at a time is small, the work efficiency is low, and the storage space is wasted, which is difficult to meet. The need for efficient transshipment and warehousing of large-sized goods. In addition, because the factory's outbound and inbound goods not only involve the transportation and storage of shuttle vehicles, but also other transportation and handling tools such as forklifts and manual trucks during the entire transportation process, plus site factors, standard pallets It is really difficult to carry goods to meet the transshipment requirements between various means of transportation.

solution

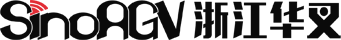

In view of the project situation, in order to meet the special-shaped steel frame trays that Shengxin Furniture is using, Zhejiang Huacha has improved the shuttle car structure as shown in the figure below and increased the size and load capacity of the shuttle car.

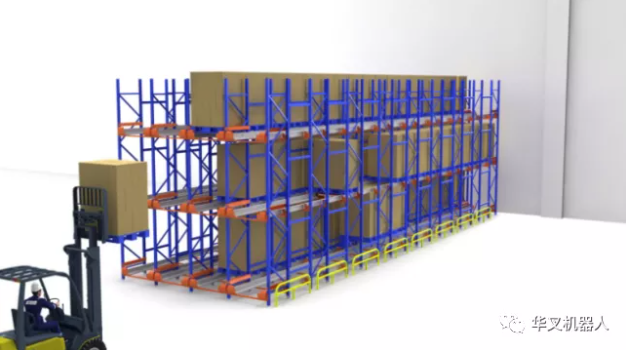

Through the improvement, the warehousing task of placing the goods at the warehousing port by a forklift truck and transporting them to the warehouse location by a shuttle vehicle is realized; Efficient, convenient, safe and flexible to solve the shuttle handling operation of non-standard pallets.

Program Highlights

1. Through the special-shaped structure design, the problem of vertical warehouse handling of the original non-standard pallets is solved.

2. The pallet can be transferred between various transport vehicles during the logistics transfer and storage.

3. The construction of horizontal shelves is realized on the slope site

Innovation and advantages

1. The body adopts a tray-submerged structure. In order to meet the pallet structure, the shuttle car is changed to a special-shaped pallet submerged type, which can effectively solve the transfer of goods carried on the pallet between various handling tools.

2. Enlarged body size and enhanced load capacity. The shuttle is aimed at the storage of finished products in the furniture industry. The single size of the finished furniture is 800*800*900mm, and the size of the shuttle is 1812*1390*187mm. The large number of cargos in a single load not only saves the space on the pallet, but also improves the efficiency of in-out and out of the warehouse.

3. Improved side rollers. The structure of the side roller group has been strengthened and the side rollers have been changed to a structure with a slope that has the ability to correct deviation.